PETROLEUM ENGINEERING

DEPARTMENT PROFILE

Petroleum Engineering Department has started its functioning from the Academic Year 2009-10. Petroleum engineering is a field of engineering concerned with the activities related to the production of hydrocarbons, which can be either crude oil or natural gas. Exploration and Production are deemed to fall within the upstream sector of the oil and gas industry. Petroleum Engineering is a combination of innovation, exploration and expansion. This program trains students in petroleum engineering and focuses primarily on exploration and production of oil and gas. This stream provides a good knowledge of many other related disciplines such as geophysics, petroleum geology, drilling, economics, reservoir simulation, reservoir engineering and gas facilities engineering.

Vision

To be recognized as the best educational institute in the field of Petroleum Engineering with a strong foundation of social and professional ethics

MISSION

Our mission is

- To produce quality petroleum engineering graduates by providing them broad knowledge of its subjects, induce team building skills, and professional values

- To create, creative learning environment work, practical exposure of the subjects by giving case studies and conducting field visits.

- To enable the students to create and apply innovative technologies in drilling, production and reservoir engineering as well as efficiently utilize their knowledge and skills to find solutions of any problems related to petroleum industry.

- To improve overall acceptability of students in industry level.

- To improve productivity of supporting staff by encouraging them for skill up-gradation.

POs

After successful completion of the program, the graduates will be able to

PO1: Apply knowledge of mathematics, science, engineering fundamentals and an engineering specialization to the solution of complex engineering problems.

PO2: Identify, formulate, research literature and analyze complex engineering problems, reaching substantiated conclusions using first principles of mathematics, natural science and engineering sciences.

PO3: Design solutions for complex engineering problems and design system, components or processes that meet specified needs with appropriate consideration for public health and safety, cultural, societal, and environmental considerations.

PO4: Conduct investigations of complex problems using research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of information to provide valid conclusions.

PO5: Create, select and apply appropriate techniques, resources and modern engineering and IT tools, including prediction and modeling, to complex engineering activities, with an understanding of the limitations.

PO6: Apply reasoning informed by contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to professional engineering practice.

PO7: Understand the impact of professional engineering solutions in societal and environmental contexts and demonstrate knowledge of, and need for sustainable development.

PO8: Apply ethical principle and commit to professional ethics and responsibilities and norms of engineering practices.

PO9: Function effectively as an individual, and as a member or leader in diverse teams and in multidisciplinary settings.

PO10: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clean instructions.

PO11: Describe knowledge and understanding of engineering management principles and apply these to one’s own work, as member and leader in a team and to manage projects in multidisciplinary environments.

PO12: Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

PEOs

Graduates of the program will

PEO 1: Be successful in diverse career paths in the petroleum or allied industries.

PEO 2: Enhance problem-solving skills that involve designing and conducting experiments, analyzing and interpreting data.

PE0 3: Continue professional development by active participation in professional society activities.

PEO 4: Display lifelong learning through continuing education or postgraduate education.

PSOs

PSO1: An ability to understand basic components of petroleum engineering operations.

PSO2: An ability to analyses, formulate and design to produce solution that meets specific needs of the industry.

Petroleum Engineering Department provides full-fledged resource labs to the students in the areas of:

Constitution of the Board of Studies - Department of PETROLEUM ENGINEERING

| Name | Designation |

|---|---|

Dr. Charan Kumar Ala | Head of the Department, Chairperson-BoS |

Dr M V S Babu | Professor and Dean |

Dr. Ravi Gujjula | Chief General Manager, APSSDC, Vijayawada. |

Dr. C V Subrahmanyam | Professor & Head, Department of Chemical Engineering |

Mr. M V S V Prasad | Lead Manager, RIL, Kakinada. |

Mr. Dakejaswanth Roy | Assistant Professor, PE & PCE Department, JNTUK |

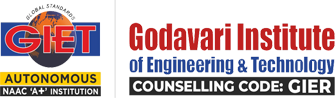

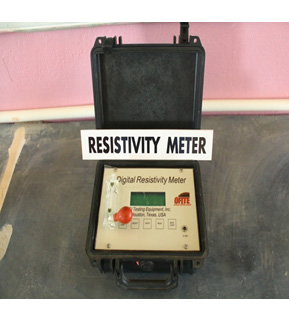

Drilling Fluids Laboratory

Petroleum Analysis Laboratory

Instrumentation Process Dynamics & Control Laboratory

Petroleum Reservoir Engineering Laboratory

Academic Year:2020-2021 |

|---|

Raju, C. H. A. I., Pratyusha, K. V. D., Lakshmi, N. N., Raju, P. R., Prasad, G., & Yugandhar, N. M. (2021). Studies on development of microbial fuel cell for waste water treatment using bakers yeast. Materials Today: Proceedings, 44, 683-688. |

Academic Year:2019-2020 |

Gangadhar, M., Shadulla, S., & Kumar, K. S. (2020). Development of a Model for the Intensified Mass Transfer Coefficients by the Insertion of Three Sided Objects Across Vertical Conduits. Development, 7(12). |

Gangadhar, M., Kumar, K. S., & Uday, K. (2020). Comparative Performance Evaluation of Four Stroke Diesel Engine using Methyl PalmKernel Ester as Alternative Fuel. International Journal of Advanced Science and Technology, 29(5), 10611 – 10616. |

Gangadhar, M., Kumar, K. S., & Uday, K. (2020). Model Development for the Augmented Momentum Transfer Coefficients across Vertical Conduits using Three Sided Equilateral Plates as Insert Promoters. Journal of Advance Research in Dynamical & Control Systems, 12(6). |

Academic Year:2018-2019 |

Ansari, M. I., Siddique, M. H., Samad, A., & Anwer, S. F. (2019). On the optimal morphology and performance of a modeled dragonfly airfoil in gliding mode. Physics of Fluids, 31(5). |

Academic Year:2017-2018 |

Raju, C. A. I., & Nethi, N. V. (2018). Congo red dye removal using hydrilla verticillata powder and optimization through Box BEHNKEN design. International Journal for Research in Applied Science and Engineering Technology, 6(3), 1506-1521. |

Siddique, M. H., Afzal, A., & Samad, A. (2018). Design optimization of the centrifugal pumps via low fidelity models. Mathematical Problems in Engineering. |

Mrinal, K. R., Siddique, M. H., & Samad, A. (2018). Performance prediction of a centrifugal pump delivering non-Newtonian slurry. Particulate Science and Technology, 36(1), 38-45. |

Academic Year:2016-2017 |

Siddique, M. H., Samad, A., & Husain, A. (2017). Combined effects of viscosity and surface roughness on electric submersible pump performance. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 231(4), 303-316. |

Sharif, M. D. A., Nagalakshmi, N. V. R., Reddy, S. S., Vasanth, G., & Sanker, K. (2017). Drilling waste management and control the effects. Journal of Advance Chemical Engineering, 7(1), 166. |

Sharif, M. D. A., Nagalakshmi, N. V. R., & Reddy, S. S. (2017). Advance technique to increase production from tight formations using HiWAY Flow-Channel Hydraulic Fracturing Technique. Journal of Advance Chemical Engineering, 7(1). |

Siddique, M. H., Bellary, S. A. I., Samad, A., Kim, J. H., & Choi, Y. S. (2017). Experimental and Numerical investigation of the performance of a centrifugal pump when pumping water and light crude oil. Arabian Journal for Science and Engineering, 42(11), 4605-4615. |

Bellary, S. A., Siddique, M. H., Samad, A., Sangwai, J. S., & Chon, B. (2017). Effects of crude oil-water emulsions at various water-cut on the performance of the centrifugal pump. International Journal of Oil, Gas and Coal Technology, 16(1), 71-88. |

Bellary, S. A. I., Adhav, R., Siddique, M. H., Chon, B. H., Kenyery, F., & Samad, A. (2016). Application of computational fluid dynamics and surrogate-coupled evolutionary computing to enhance centrifugal-pump performance. Engineering Applications of Computational Fluid Mechanics, 10(1), 171-181. |